Last updated on April 28, 2021

Many projects experience lower than expected productivity and substantial delays in production processes. Thus, they miss out on great business opportunities, something you can’t afford in today’s highly competitive market.

One central reason why projects struggle with hitting operational targets is a lack of focus on operational readiness during the early phase of the project. Even established, experienced companies tend to underestimate the amount of attention operational readiness requires and fail to account for the consequences.

Hence, studies suggest that poor start-up activities such as operational readiness can cause large companies to lose 20% to 40% of their net present value.

What is Operational Readiness and What Does it Require?

Operational readiness refers to the capability to efficiently deploy, operate, and maintain procedures and systems. The core purpose of operational readiness is to eliminate operational risks or losses incurred due to failed or inadequate internal systems, people, processes, or external issues.

Oftentimes, project team members ramp-up a project and leave, after which the processes fail. The underlying reason behind failure is the absence of a solid plan for efficient transitioning of the facility to the operations team that will be running it. When operational readiness is not taken seriously, projects fail to deliver the promised results.

The reason why operational readiness is neglected is that it’s not part of the product lifecycle. Once a solution is ready for deployment, the job of the project team and project manager is complete. That’s when ‘release management’ or ‘solution delivery’ takes over. Operational readiness helps streamline the transition from project work to operations.

For smooth and sustainable operational readiness, you must ensure that users are trained and have easy access to documentation. Moreover, the user support procedure must also be operational and documented.

On top of that, the staff must also be trained on operating and maintaining the systems, while the operating procedures should be documented. In addition, the readiness specialists must be independent of the project staff and be autonomous.

Ideally, the staff must be prepared to manage operational risks, take ownership of the risk management plan, which outlines contingency and recovery procedures to address situations like a security breach, system crash, and so on.

All operational readiness costs must be considered when developing the business case for the project and readiness risks should be accounted for in project governance.

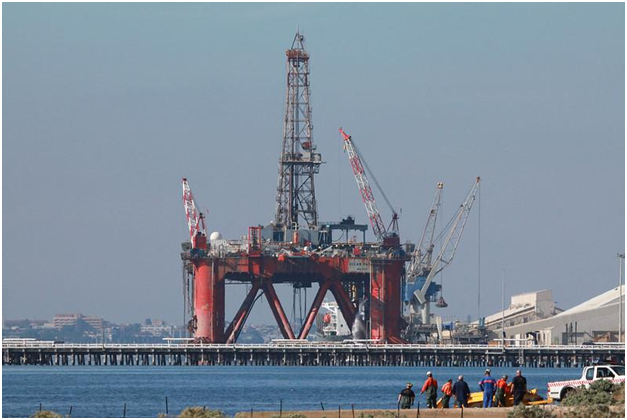

If you’re a rig startup, seek drilling rig consulting services to ensure operational readiness. Let’s now look into how readiness can be achieved.

Steps to Achieve Operational Readiness in Projects

Follow these key steps to achieve operational readiness:

Engage the Client’s Team Early and Effectively

It usually takes around one or two years to get a plant and its people in a smooth-running state. The people who are supposed to make the facility work, including the Ops General Manager, CEO, and COO, need to be engaged early on.

This way, they are able to adapt to the processes quickly and project managers and their teams quickly resolve any issues or eliminate bottlenecks that may arise.

Bringing in operations specialists early on gives them the time they need to prepare. They are able to understand what’s already in place, where the challenges and risks lie, and identify the status quo.

Also, they get to know what degree of maturity is required by projects. In other words, early engagement eliminates the disconnect between what the specialists need and what project teams have done to facilitate a good start.

Get the Design Right

When it comes to design, delaying the operational readiness piece often creates problems. This can increase engineering costs and time consumption. There can be a disconnect between the operations people and the project team in terms of expectation.

As a result, managing expectations is critical. That can be done using efficient knowledge-transfer methods. Project outputs such as planning, engineering, and designing are the inputs for operational readiness. The knowledge transfer method you choose should make this easier to understand.

Again, getting the design right involves engaging the right players up front. Engaging them later on in the process can prove expensive.

Besides the operations staff, engage those handling non-process related tasks, too. Moreover, plan the fundamental aspects. For instance, figure out what equipment, tools, and permits are needed and whether or not training rooms are required.

Keep in mind that successful operations are created during the build process. Integrating the operating strategy and commission plan with the construction and design sequencing helps minimize the project schedule and risks associated with design changes.

Recognize the Role Played by Culture

Culture plays a significant role in project success or failure. When project rescue work executed well with appropriate change management, they transition seamlessly into operations. The goal should be team empowerment so that they can manage processes themselves while the readiness specialists guide them.

Be Transparent

Use a management system and approach that creates transparency and openness to address challenges and issues. By focusing on deliverables and aligning them with actions, goals, and results, you should be able to make better estimates about the amount of effort required for operational readiness.

Optimize Capability Development and Resource Allocation

Devise a detailed plan, outlining how you wish to deploy training that focuses on critical knowledge requirements and start-up skills.

You should know exactly when to bring in the right people to foster an optimal onboarding process. If you have a well-trained and organized staff, the hand over process will be extremely easy.

Final Word

Organizations understand how challenging it can be to transition project deliverables into a solution that proves effective in operation. However, following the above explained steps can make the transition remarkably easy and sustainable.

Author Bio

Claudette leads the marketing initiatives for Epeus Group and regularly produce market insights papers for Upstream Oil & Gas and Renewable sectors. She’s an experienced business, reporting and market analyst, with several years’ experience in Upstream Oil & Gas and Financial Services.