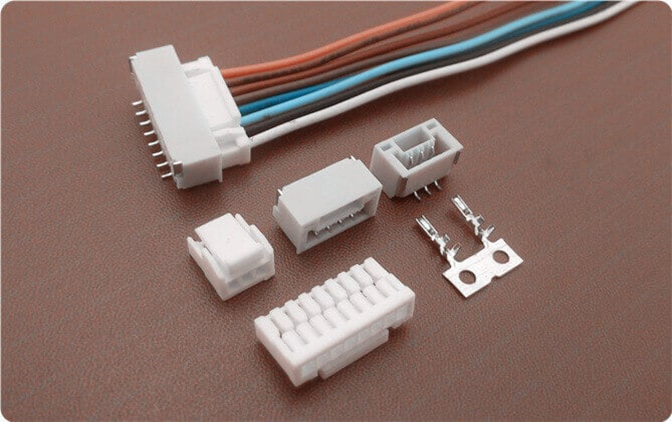

PicoBlade Connectors are suitable for both prototype and scale production. The connector System includes a frictional lock for mating retention and a two-point contact design for a secure electrical connection. Because severe applications are prone to stress, vibration, and rough handling, which can cause terminals to get dislodged and cause signal interference, customers desire greater reliability and longevity.

Picoblade connectors with a diameter of 1.25mm have a friction lock and a reliable two-point contact design. PicoBlade Wire-to-Board Connector users have indicated a need for higher electrical conductivity than the Tin-plated versions now available.

Features and Applications of PicoBlade connectors

Picoblade connectors come in a flash and are 0.38m gold-plated for increased consistency and durability in dire circumstances. Their compact size makes it easier to uses in various applications across all industries. The connector’s two-point contact design ensures a secure electrical connection in low-current, low-voltage, and high-vibration environments.

PicoBlade connections for SMT vertical headers come with an optional vacuum cover, enabling high-volume installation using industry-standard pick-up nozzles. This unique characteristic saves about 45 percent of the PCBs surface area. PicoBlade connectors come in wire-to-board and wire-to-wire configurations. With surface mount and through-hole headers, it’s a two- to the fifteen-circuit single-row system.

A broad range of automated, semi-automatic, and manual equipment is available to help with crimp harness construction utilizing different wires. PicoBlade connectors are utilized in a variety of applications because of their characteristics.

PicoBlade connections are critical to the automobile industry’s operations. Apart from the automotive sector, PicoBlade connectors have shown magnificent uses in combination switches, computers, monitors, desktops, smart TVs, laser printers, drones, servers, processors, hospital equipment, aviation, military, and many more. They’re flexible, long-lasting, and provide great signal integrity while taking up less area in the application.

Using the PicoBlade connectors

PicoBlade connections’ tiny size and distinctiveness are interesting in that they appear difficult yet are relatively simple to build. With the right tools and precision, anyone can easily make the connectors at their homes. Perhaps, this is one of the features that everyone tends to overlook. It is this simplicity that has made the connectors popular and feasible among various sectors.

Tip 1:

Take a thin wire and strip its tip with the help of a wire cutter. A wirecutter is a typical instrument for cutting wires of various materials such as brass, steel, iron, and copper. It features insulated handles to prevent you from being shocked by the wires you’re cutting. The cables used in these connectors are either copper or steel because of their magnificent conducting properties.

Make sure the insulation part is orderly removed, and a clear wire is visible at the top. The optimum exposition is one-eighth of an inch.

Tip 2:

Take the connector body and slide the exposed part of the wire inside the female side of the connector. The connector has two sets of tabs it will bend over; one on the wire itself and the other on the insulation.

Use compression tools to further accelerate the process. These are designed for this type of pin. They are readily available at any local vendor, or you can buy them online. These tools are for cold welding connections between two wires; or a wire and a connector, such as lugs.

Now, slide the wire in the pin until it gets centered in the first set of tabs. Then compress it down by applying the pressure. This will seal it up properly. Then do the same process with the other set of tabs. The wire is now connected to the pin.

Tip 3:

Take the ready wire and insert it in the back of the connector plug socket. Connector plugs are readily available in the market and various online portals. On the back of the connectors, there are specific numbers imprinted. If unable to see with naked eyes, take the help of a magnifying glass to carefully get the number system. Now, insert the wire and tuck it in properly. To check the insertion, slightly pull it back.

The PicoBlade connectors are ready to use.

Tip 4:

It is common to place the wire in the wrong location since the numbers on the back of the connectors are visible. And sometimes, if you feel the need to remove the wire or change it, then do not make the mistake of simply pulling it out. It does not work that way. It will only break the wire, and the connector will become useless.

Use a de-pinning tool specifically designed for these connectors. Insert the depinning tool from the free end of the connector into the hole where the wire is. Now, when the de-pinning is over the pin, push the center plunger, and the wire will be extracted.

The Parting Words

It is not rocket science to make PicoBlade connectors at home. These are hidden magical gems that are present inside the bodies of our devices. They are present everywhere and without any ROI making our lives easier. In the wire-to-wire and wire-to-board connections, PicoBlade connectors have established their dominance.